Osto qui visto che l’ho citato pochi commenti sopra:

‘Jury still out’ on engine choice for A320neo replacement but RISE appears ascendant

Airbus insists it is still evaluating all engine options for its future Next-Generation Single Aisle (NGSA) even as it readies for flight tests of the CFM International RISE open-fan demonstrator aboard an A380 testbed later in the decade.

CFM touts the RISE as offering the greatest potential fuel-burn improvement of any next-generation engine – a 20% jump over the current Leap series – partly due to a bypass ratio of around 60:1, far greater than can be achieved on even future ducted turbofans.

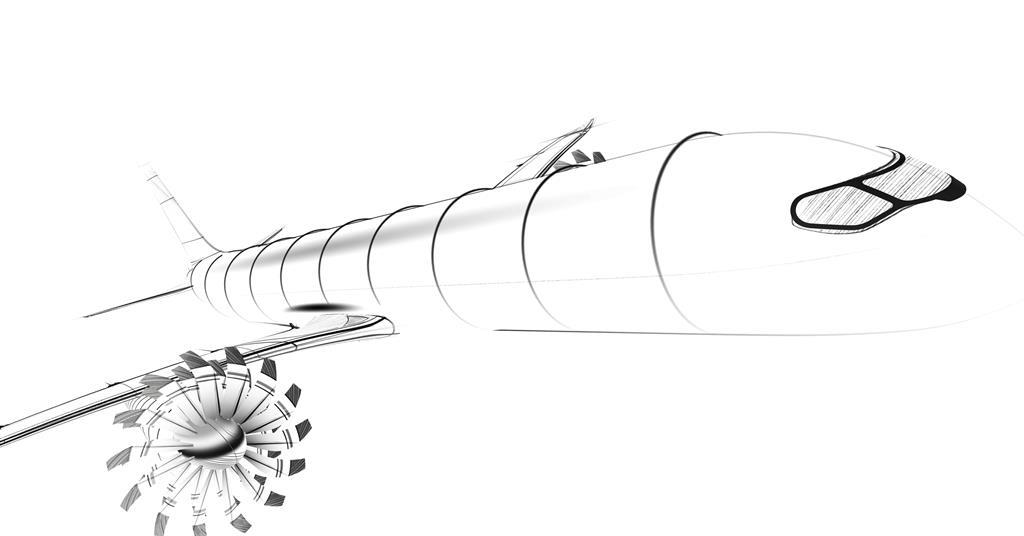

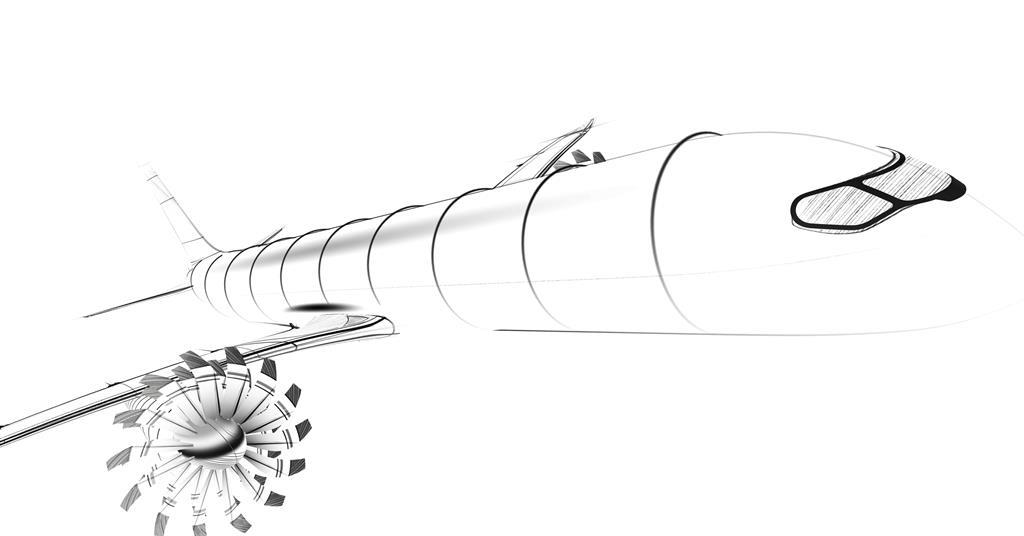

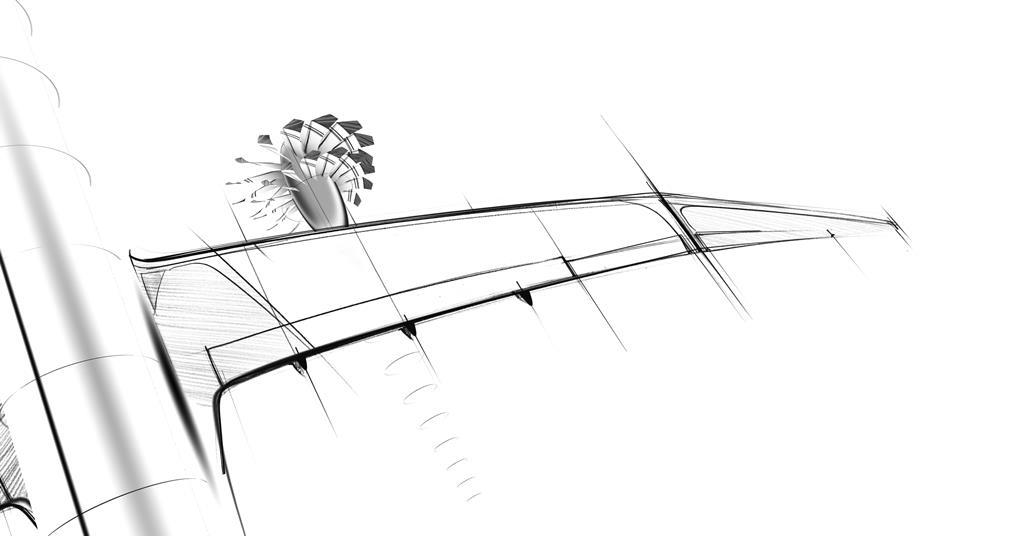

While yet to select the RISE for the NGSA, which is likely to enter service in the second half of the next decade, Airbus clearly has a preference for the powerplant if it can deliver the performance promised, displaying at its Summit event in Toulouse several concept images of the future narrowbody equipped with open-rotor engines.

Speaking to FlightGlobal at the Summit on 25 March, Frank Haselbach, Airbus senior vice-president of propulsion integration, said that if the open-rotor design works “it will be very, very powerful” and offers the “biggest potential” of any future propulsion choice.

But with the engine-airframe integration significantly different from that required for a conventional ducted fan, Airbus believes that work needs to take place early in the development to ensure the full performance gain can be realised.

“We will only find that out if we do the integration for a flight test because that also underpins what we are doing for a potential vision product,” says Haselbach.

“That doesn’t mean that we will inevitably have made the decision; we are looking at this because it has the biggest potential.”

Other engine manufacturers – notably Pratt & Whitney but possibly also Rolls-Royce – will also have the chance to “show us their potential in terms of the next-generation of ducted fans”, offering a bypass ratio of around 15:1, he says.

However, the “integration there is cleaner, is clearer, it’s a bit more evolutionary” and while work on this topic is ongoing “that’s just not at the same scale, because it’s not the same reward”.

Speaking at the same event, Christian Scherer, chief executive of Airbus commercial, says “the jury is still out” on the engine for the NGSA, and whether it would follow the current model of offering a choice between different powerplant options.

In either case, he says, “the technology needs to be proven” and must enable Airbus to build a “superior product” in terms of its fuel burn and environmental performance.

“Today we have a lot of hopes in the [RISE] engine… because by definition it brings lower fuel burn,” he says. “It doesn’t mean we are discounting the other choices.”

Notably, images displayed at the Summit also included a version of the NGSA with ultra-high-bypass-ratio ducted-fan engines.

Key integration challenges include mitigating the possible higher levels of noise and vibration to achieve “the same comfort and same cabin noise as the aircraft of today”, says Haselbach.

“We have done a lot of simulations together. We have looked at this to make sure we have definitely achieved the same comfort level and noise footprint as the current version of aircraft; we don’t want any step backwards there.”

Shielding will also have to be added to the fuselage to prevent penetration by debris in the “unlikely event” of a blade release.

We are also working with CFM to make sure the blade is as light as possible and as slow as possible if it would release.”

While the shielding will “add some mass” to the airframe – already factored into the overall fuel-burn improvement calculation – it has a secondary benefit as it “also helps to manage the sound pressure level in the cabin very, very positively”.

Airbus is working to optimise the wing for an open-fan design, noting the change to the airflow over the wing surface and the need to raise the height of the engine through a “slight gulling in the wing” to ensure sufficient ground clearance for the large-diameter fan.

Those challenges are being explored through the airframer’s Wing of Tomorrow programme.

Airbus is also studying the option of tail-mounted open-fan engines “which could have some benefits on the noise side”, he adds.

The engine manufacturer continues component and subsystem testing to “mature every technology and component to prove the endurance, durability and reliability and obviously the fuel-burn advantage,” says Mohamed Ali, chief technology and operations officer at GE Aerospace, which jointly owns CFM with Safran Aircraft Engines.

“We just continue doing that methodically, coming up the learning curve on both the technology readiness level and the manufacturing readiness level, leading up to the flight-demonstrator programme.”

There is, as yet, no firm date for the A380 flight tests other than they will take place “later this decade” – likely in the 2027-2028 timeframe – but the RISE will first fly aboard GE’s Boeing 747 testbed, says Ali.

“There’s some validation we have to do internally as CFM and as GE Aerospace – get some more results, validate proof it out – and then it goes on the A380,” he says.

Haselbach says the RISE engine will perform a “mini-flight envelope” campaign “in the real world” followed by a “a full flight envelope here in Toulouse” prior to the powerplant’s installation in the inboard left-hand position on the A380 testbed.

Elsewhere, Airbus is maturing multiple technologies – new materials, wing designs, and greater levels of electrification – for possible inclusion in the NGSA, which is intended to offer a fuel-burn improvement of up to 30% at aircraft level.

“Step by step we will come to the magic recipe that will make this fourth revolution [of aviation] possible,” says Bruno Fichefeux, head of future programmes. “We are not yet at the level of the recipe we are at the level of the ingredients.”

“I think we have clearly stated and demonstrated that this next generation of aircraft will be radically different from what we are doing today,” adds Karim Mokkaden, head of aircraft of tomorrow R&T.

“We are not doing it for the sake of technology tourism – we are doing it because we really need those technologies to get to the performance we want to reach.”

www.flightglobal.com

www.flightglobal.com

‘Jury still out’ on engine choice for A320neo replacement but RISE appears ascendant

Airbus insists it is still evaluating all engine options for its future Next-Generation Single Aisle (NGSA) even as it readies for flight tests of the CFM International RISE open-fan demonstrator aboard an A380 testbed later in the decade.

CFM touts the RISE as offering the greatest potential fuel-burn improvement of any next-generation engine – a 20% jump over the current Leap series – partly due to a bypass ratio of around 60:1, far greater than can be achieved on even future ducted turbofans.

While yet to select the RISE for the NGSA, which is likely to enter service in the second half of the next decade, Airbus clearly has a preference for the powerplant if it can deliver the performance promised, displaying at its Summit event in Toulouse several concept images of the future narrowbody equipped with open-rotor engines.

Speaking to FlightGlobal at the Summit on 25 March, Frank Haselbach, Airbus senior vice-president of propulsion integration, said that if the open-rotor design works “it will be very, very powerful” and offers the “biggest potential” of any future propulsion choice.

But with the engine-airframe integration significantly different from that required for a conventional ducted fan, Airbus believes that work needs to take place early in the development to ensure the full performance gain can be realised.

“We will only find that out if we do the integration for a flight test because that also underpins what we are doing for a potential vision product,” says Haselbach.

“That doesn’t mean that we will inevitably have made the decision; we are looking at this because it has the biggest potential.”

Other engine manufacturers – notably Pratt & Whitney but possibly also Rolls-Royce – will also have the chance to “show us their potential in terms of the next-generation of ducted fans”, offering a bypass ratio of around 15:1, he says.

However, the “integration there is cleaner, is clearer, it’s a bit more evolutionary” and while work on this topic is ongoing “that’s just not at the same scale, because it’s not the same reward”.

Speaking at the same event, Christian Scherer, chief executive of Airbus commercial, says “the jury is still out” on the engine for the NGSA, and whether it would follow the current model of offering a choice between different powerplant options.

In either case, he says, “the technology needs to be proven” and must enable Airbus to build a “superior product” in terms of its fuel burn and environmental performance.

“Today we have a lot of hopes in the [RISE] engine… because by definition it brings lower fuel burn,” he says. “It doesn’t mean we are discounting the other choices.”

Notably, images displayed at the Summit also included a version of the NGSA with ultra-high-bypass-ratio ducted-fan engines.

Key integration challenges include mitigating the possible higher levels of noise and vibration to achieve “the same comfort and same cabin noise as the aircraft of today”, says Haselbach.

“We have done a lot of simulations together. We have looked at this to make sure we have definitely achieved the same comfort level and noise footprint as the current version of aircraft; we don’t want any step backwards there.”

Shielding will also have to be added to the fuselage to prevent penetration by debris in the “unlikely event” of a blade release.

We are also working with CFM to make sure the blade is as light as possible and as slow as possible if it would release.”

While the shielding will “add some mass” to the airframe – already factored into the overall fuel-burn improvement calculation – it has a secondary benefit as it “also helps to manage the sound pressure level in the cabin very, very positively”.

Airbus is working to optimise the wing for an open-fan design, noting the change to the airflow over the wing surface and the need to raise the height of the engine through a “slight gulling in the wing” to ensure sufficient ground clearance for the large-diameter fan.

Those challenges are being explored through the airframer’s Wing of Tomorrow programme.

Airbus is also studying the option of tail-mounted open-fan engines “which could have some benefits on the noise side”, he adds.

The engine manufacturer continues component and subsystem testing to “mature every technology and component to prove the endurance, durability and reliability and obviously the fuel-burn advantage,” says Mohamed Ali, chief technology and operations officer at GE Aerospace, which jointly owns CFM with Safran Aircraft Engines.

“We just continue doing that methodically, coming up the learning curve on both the technology readiness level and the manufacturing readiness level, leading up to the flight-demonstrator programme.”

There is, as yet, no firm date for the A380 flight tests other than they will take place “later this decade” – likely in the 2027-2028 timeframe – but the RISE will first fly aboard GE’s Boeing 747 testbed, says Ali.

“There’s some validation we have to do internally as CFM and as GE Aerospace – get some more results, validate proof it out – and then it goes on the A380,” he says.

Haselbach says the RISE engine will perform a “mini-flight envelope” campaign “in the real world” followed by a “a full flight envelope here in Toulouse” prior to the powerplant’s installation in the inboard left-hand position on the A380 testbed.

Elsewhere, Airbus is maturing multiple technologies – new materials, wing designs, and greater levels of electrification – for possible inclusion in the NGSA, which is intended to offer a fuel-burn improvement of up to 30% at aircraft level.

“Step by step we will come to the magic recipe that will make this fourth revolution [of aviation] possible,” says Bruno Fichefeux, head of future programmes. “We are not yet at the level of the recipe we are at the level of the ingredients.”

“I think we have clearly stated and demonstrated that this next generation of aircraft will be radically different from what we are doing today,” adds Karim Mokkaden, head of aircraft of tomorrow R&T.

“We are not doing it for the sake of technology tourism – we are doing it because we really need those technologies to get to the performance we want to reach.”

‘Jury still out’ on engine choice for A320neo replacement but RISE appears ascendant

Airbus insists it is still evaluating all engine options for its future Next Generation Single Aisle (NGSA) even as it readies for flight tests of the CFM International RISE open-fan demonstrator aboard an A380 testbed later in the decade.

Dominic Perry

Dominic Perry